Why use 3MF?

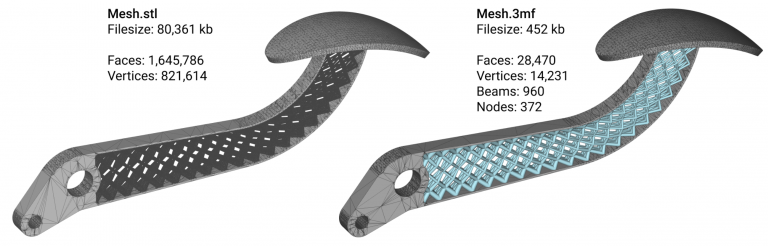

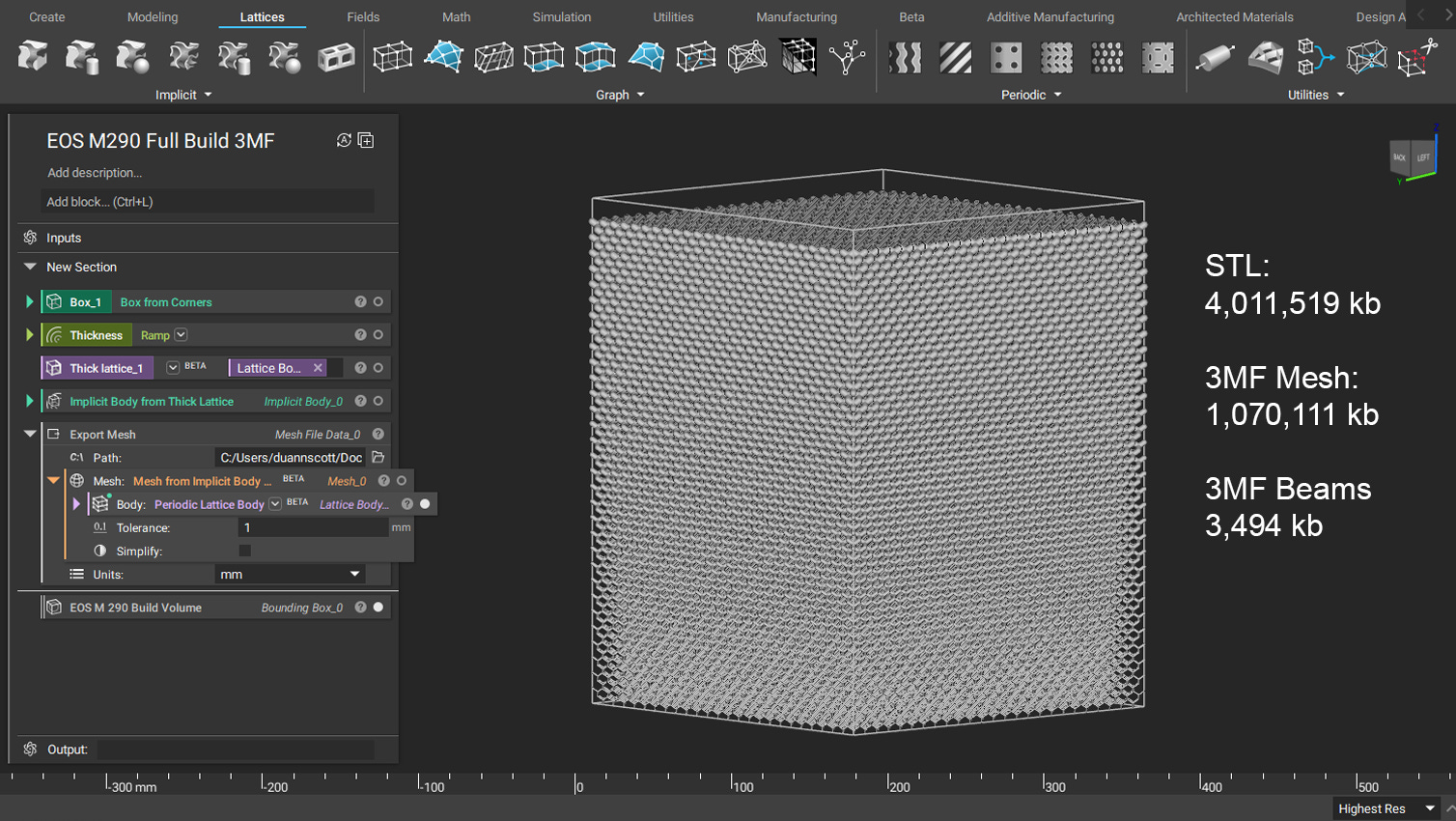

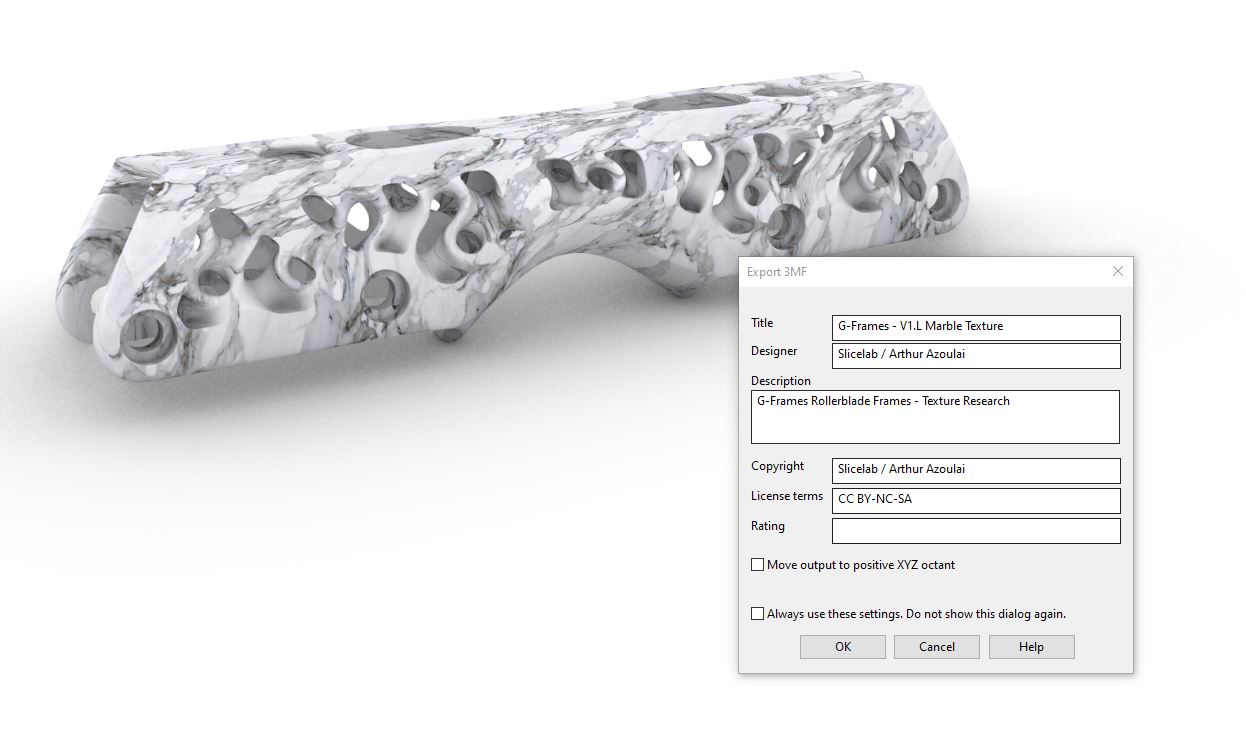

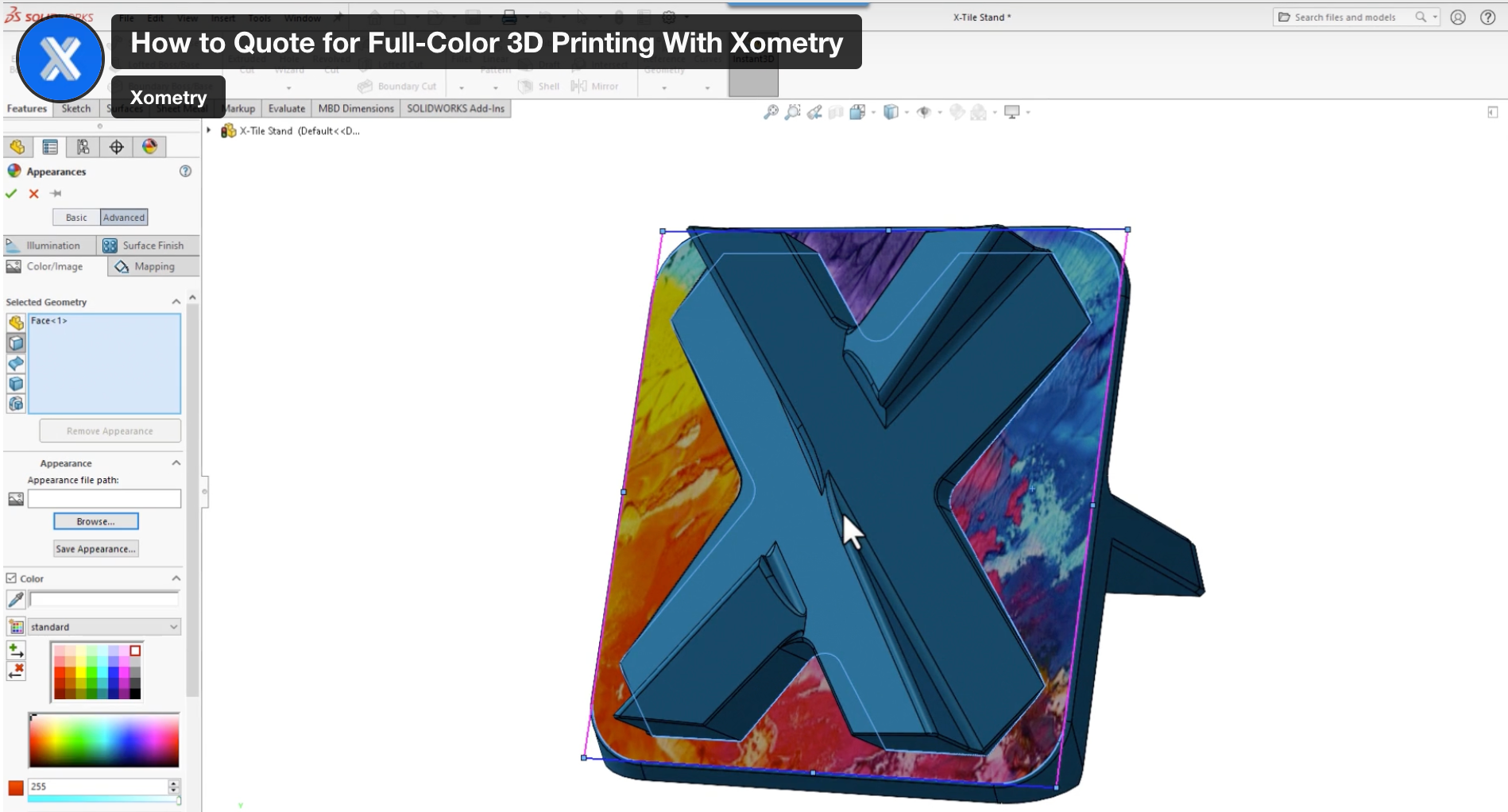

There are several reasons why 3MF is a good choice for additive manufacturing, also known as 3D printing. One of the main advantages of 3MF is that it is a modern file format that can support a wide range of 3D printing features, including color, materials, and texture, along with the efficient communication of complex lattice structures with the Beam Lattice extension, manufacturing data at the voxel level with the Volumetric Extension along with slice and security information. In contrast, older formats like STL are very basic and only support a single color with no other information.

The full specification for the 3MF format, and implementation information for developers can be found on the 3MF Github repository.

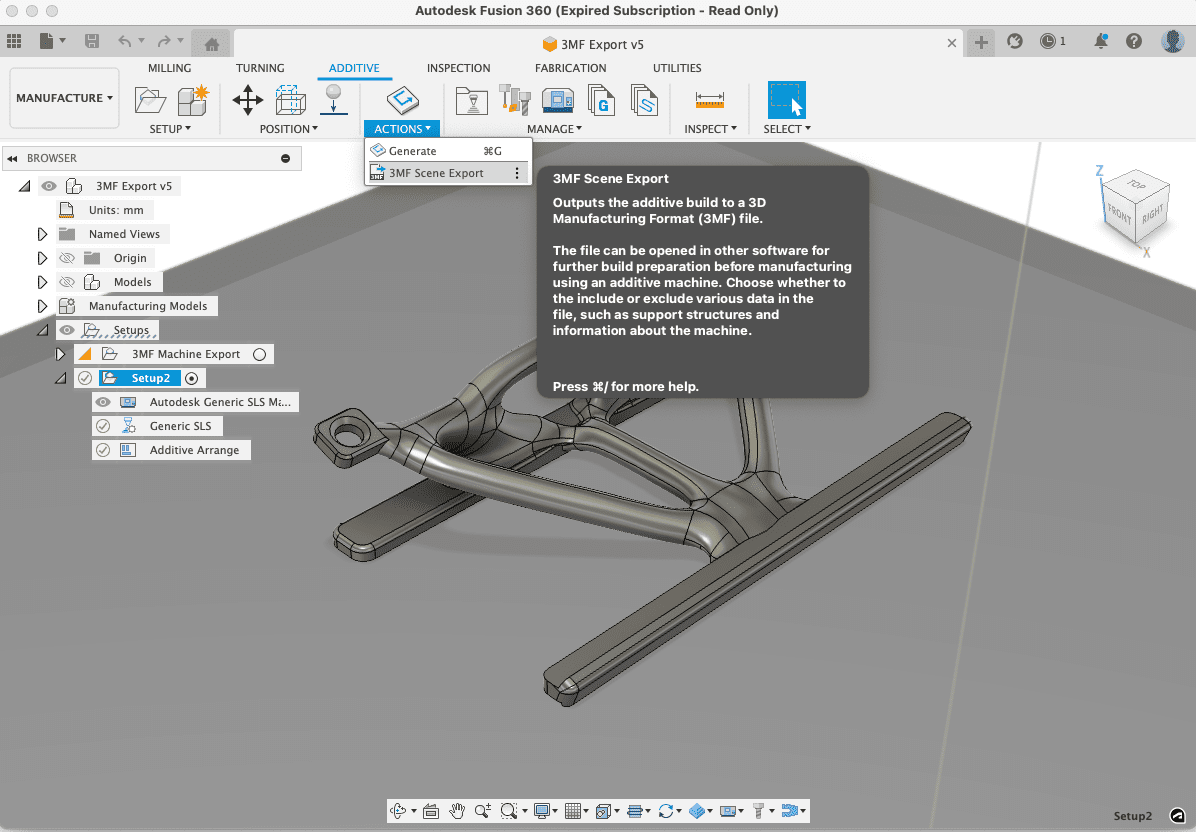

Another benefit of 3MF is that it is an open format that is supported by many different 3D printing software programs and hardware manufacturers. This means that it is easier to use and share 3MF files than other formats, which can be more difficult to work with and may not be compatible with certain software or printers.

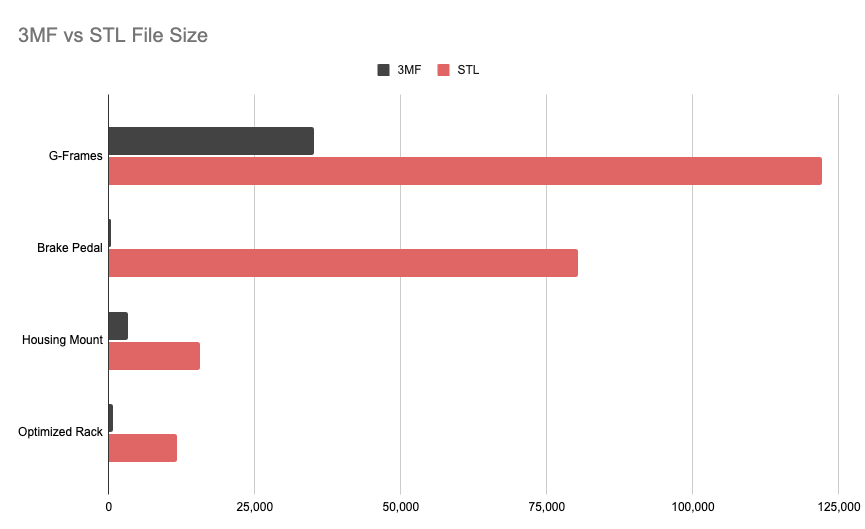

Additionally, 3MF is more efficient than some older formats. 3MF files are typically smaller in size than STL files, which means that they can be transferred and processed more quickly. This can be important in applications where speed is a concern, such as when printing large or complex 3D models.

Overall, 3MF is a versatile and flexible file format that offers several advantages for additive manufacturing. As such, it is increasingly being adopted by designers, engineers, and manufacturers as the preferred format for 3D printing.