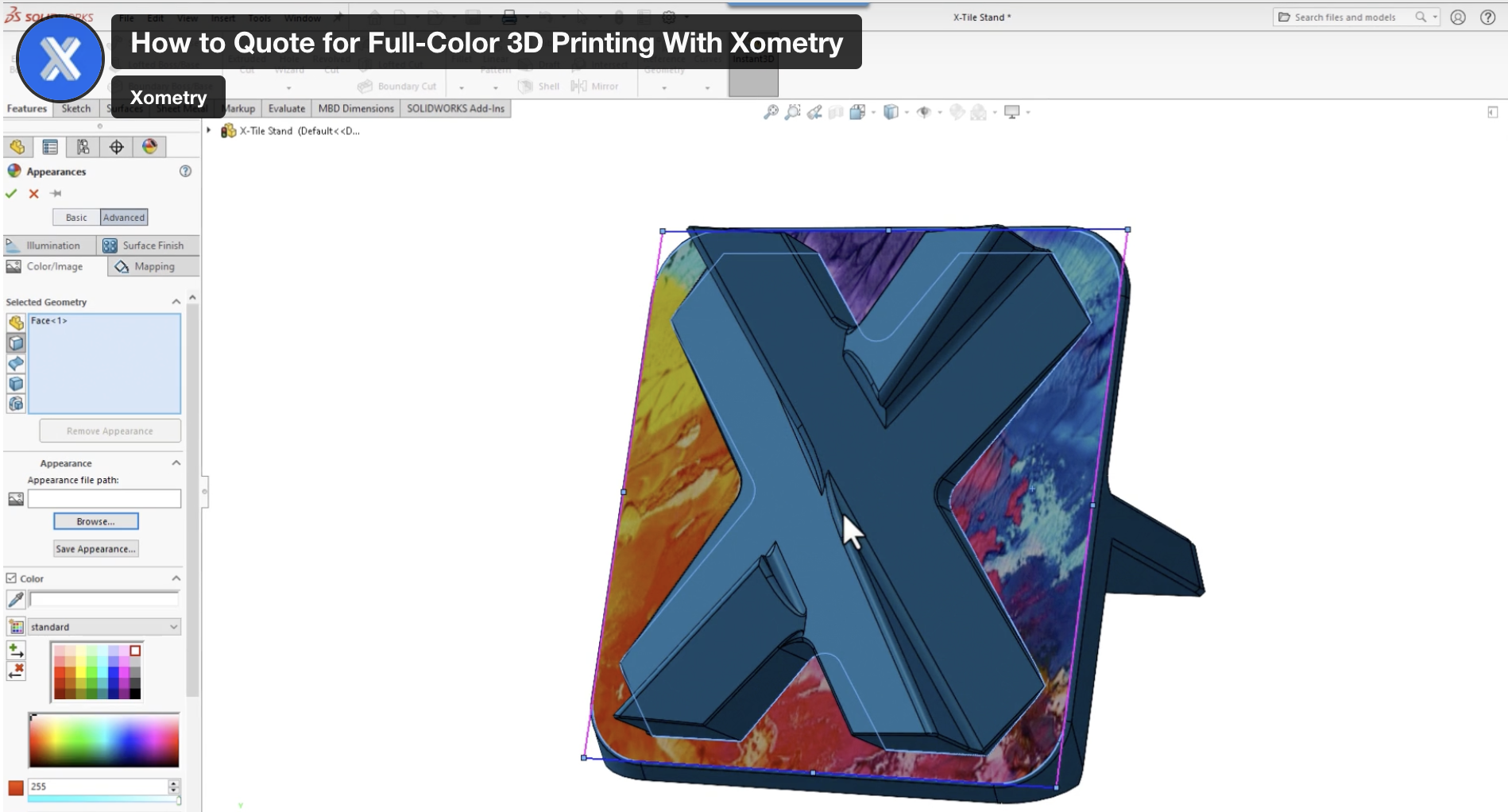

In this video, you will be introduced to Xometry’s PolyJet printing service, which is a powerful tool for creating custom full-color 3D prints. The technology allows you to print photorealistic parts with stunning details, and in multiple materials simultaneously, which makes it an ideal solution for a wide range of applications.

PolyJet technology works by using tiny droplets of liquid photopolymer that are sprayed onto a build platform layer by layer. These droplets are then cured by a UV light source, creating a solid, three-dimensional part. Because the technology uses liquid material, it is able to create incredibly fine details and produce parts with smooth surfaces that require minimal post-processing.

One of the main advantages of PolyJet technology is the ability to print in full color. This is achieved by using multiple print heads that can deposit different colors of photopolymer onto the build platform. By combining these colors in different ways, you can create parts with incredibly realistic color gradients and textures, making it ideal for creating visual prototypes, architectural models, and other applications where color is important.

To use PolyJet technology with Solidworks, you will need to export your 3D model as a 3MF file. This file format contains all the necessary information about your part’s geometry and color, and can be easily uploaded to Xometry’s website to get an instant quote for your custom 3D print.

With Xometry’s PolyJet printing technology, you can create stunning, photorealistic parts with incredible resolution and multiple material capabilities, making it an ideal solution for a wide range of applications.

Find out more about full color printing at Xometry.

Go to xometry.com to get an instant 3D Printing quote for your parts or project today.

————

Get an Instant Quote:

————

About Xometry:

Xometry provides 24/7 access to instant quoting and manufacturing feedback on precision CNC machining, 3D printing, sheet metal fabrication, urethane casting, and injection molding services.