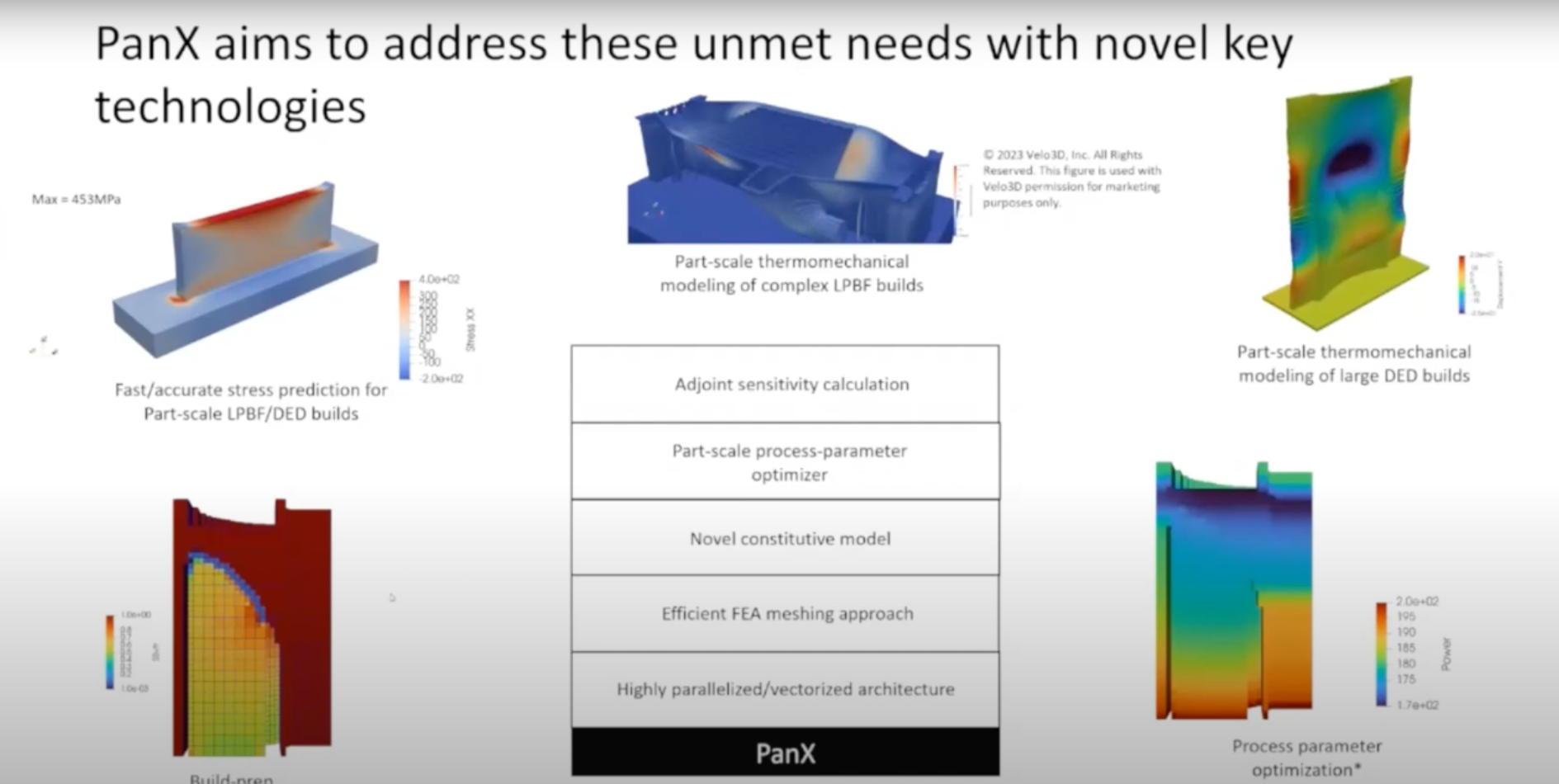

PanOptimization was founded to address the current build simulation and optimization needs of the AM market; to simulate parts of extreme geometric complexity and to not just predict print outcomes but to improve/optimize them.

Traditional AM build simulation tools do not address these needs. PanOptimization licenses the PanX solver (a finite element based engineering software) to users in the aerospace and defense, biomedical, and CAE industries, as well as machine OEMs and universities. The solver utilizes a novel architecture and FEA meshing approach which allows for fast simulation of very large and complex AM parts (e.g. heat exchangers). PanX also efficiently solves inverse problems using adjoint sensitivity analysis. Examples and use-cases of the technology will be presented.

Watch this webinar and learn more about how:

1. The PanX solver allows for efficient simulation of even the most complex AM parts.

2. The simulation/optimization approaches are applicable to both LPBF and DED processes.

3. Adjoint sensitivity analysis allows for optimization problems to be efficiently solved.

PanOptimization presenter is Erik Denlinger.

Erik Denlinger co-founded PanOptimization LLC where he currently serves as Chief Engineer. His work focuses on validating and commercializing process optimization solutions for Advanced Manufacturing. Prior to joining PanOptimization he was a stakeholder and engineer at Pan Computing LLC.

After the acquisition of Pan Computing LLC by Autodesk he became a Principal Research Engineer and Manager of Additive Process Simulation at Autodesk, where he also served as Product Owner of Netfabb Simulation and the Fusion 360 Additive Simulation Extension.

He has over a decade of experience investigating thermal and mechanical effects during AM processing and validating Finite Element models of Laser Powder Bed Fusion and Directed Energy Deposition processes.

He holds a Ph.D. in mechanical engineering from Penn State University and has coauthored over 20 technical publications, including the ASM Handbook on Additive Manufacturing Processes and a book on Thermo-Mechanical Modeling of Additive Manufacturing.