3MF in Education – Meet the MIT MassBridge Project Folks!

3D Printing (3DP) and Additive Manufacturing (AM) are on the rise, quickly becoming popular worldwide and shaking up traditional manufacturing processes. Businesses, individuals, and organizations are turning to 3DP/AM because of its great potential. As the 3DP and Additive Manufacturing industry rapidly expands, we’re also seeing a significant uptick in educational opportunities and training, which inspired our new blog series — 3MF in Education.

The goal of this blog series is to share stories about schools teaching 3MF in their curriculum and how they plan to educate future generations of designers for 3DP and AM. In this post, we’ll discuss how the MassBridge Project contributes to the education and training of people entering the 3DP and AM space.

Summary of the MassBridge Project

Near-term and long-term workforce issues are at the forefront of our nation’s mind due to an aging workforce, a disconnect between training programs and industry needs, and a lack of awareness regarding opportunities for advancement. While these challenges are not unique to Massachusetts, the solutions provided by the Commonwealth’s MassBridge program to address them might provide a blueprint for others to follow.

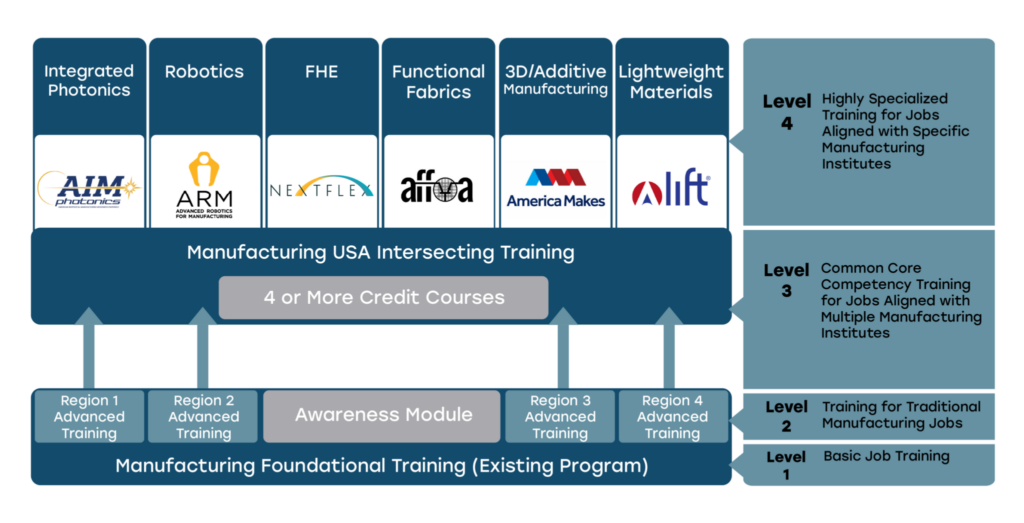

In 2020, the U.S. Department of Defense’s Manufacturing Technology Program (DoD ManTech) awarded Massachusetts a $3.2 million grant to design an effective state-based manufacturing technician training and career pathway model to meet the needs of manufacturers. The MassBridge Project aims to invigorate manufacturing technician education programs at community colleges by adding new skills and abilities into the curriculum so that students will be well-equipped for future workforce demands.

The Strategy

MassBridge is led by the Massachusetts Center for Advanced Manufacturing and a team of MIT experts, industry, community colleges, vocational high schools, and federal and state agencies. The MassBridge Program includes the revision of manufacturing curricula at 7 Massachusetts community colleges to align with the high-priority skill requirements for advanced manufacturing technicians.

In this interview, we had the chance to catch up with 3 key contributors to the MassBridge Project, including Elizabeth A. Moore, a Research Scientist at the Massachusetts Institute of Technology (MIT) in the Materials Systems Lab and the initiative for Knowledge in Innovation and Manufacturing, Beth Unger, a creative with extensive experience in the academic, nonprofit, and industry fields, and Fredrick Bsharah. He brings over 30 years of knowledge in various industries, including the automotive and aerospace industries.

Q&A

Tell us a little about your institution and your role.

Elizabeth A. Moore: I am a Research Scientist at MIT in the Materials Systems Lab and the Initiative for Knowledge in Innovation and Manufacturing, and I conduct research that investigates emerging technology systems’ environmental, economic, and social challenges. My Master’s and Ph.D. are in Sustainable Systems from Rochester Institute of Technology (RIT).

In 2018, I was a Visiting Scientist at the United Nations University for Environment and Human Security, where I worked with a team to assess the geospatial information capacity of countries for disaster risk reduction. My current projects include advanced manufacturing workforce road mapping, mineral, and commodity market analysis, and economic and environmental modeling of hydrogen production technologies.

Beth Unger: I am creative and like building impactful processes. My Master’s and Ph.D. are from the University of Iceland, with a Ph.D. dissertation focusing on renewable energy and cross-border energy trading in the Nordic electricity market. I have broad, well-rounded experience in academic, nonprofit, and industry fields, including international work experience in the transportation energy sector.

Fredrick Bsharah: I have over 30 years in the automotive and aerospace industries as a senior technical specialist and product development engineer. My current areas of interest include 3D solid modeling, additive manufacturing practices, robotics, quality, and product lifecycle management (PLM). I have extensive participation and leadership in the ANSI, SASIG, OMG, and ISO standards communities, including the AIAG Collaborative Engineering & Product Development Steering Committee, PDES Inc. industry cooperative, and ISO STEP Product Data Management (PDM) Roundtable. My degrees are in Civil/Structural Engineering (University of Notre Dame) and Engineering Systems (UCLA); I am also certified as a SOLIDWORKS Accredited Educator and a Quality Six Sigma Black Belt.

What inspired you to be part of the project?

Elizabeth A. Moore: It was 3 things for me, increased automation in manufacturing, the labor shortage, and skills gaps.

The U.S. is working to have a more robust and reliable supply of goods by rebuilding manufacturing and investing money into it. However, there remains a critical gap that must be addressed to build back the U.S. manufacturing industry—the U.S. manufacturing workforce. A labor shortage and a skills gap are especially severe in advanced manufacturing sectors such as additive/3D manufacture. Despite increased automation in manufacturing, the demand for labor, particularly middle-skilled labor*, is increasing. Investing in workforce development is critical to understand these gaps and informing future training.

*Middle-skilled workers are often defined as those with an education level that is greater than a high school diploma and less than a Bachelor’s degree

Beth Unger: I was the student in the classroom, continuously asking the teacher, “When, where, and how am I going to use this?” Most often, the answer was, “When you start working.” Unfortunately, the humdrum response left me unmotivated, uninspired, and directionless. MassBridge is an industry-driven project that makes a meaningful connection between industry and classroom learning. And the model we create in the Commonwealth of Massachusetts must be scalable and replicated in other parts of the U.S. I wanted to be part of it by showing students when, where, and how they will apply the lessons while positively impacting the U.S. manufacturing industry.

Fredrick Bsharah: For me, it was a natural fit. Our Engineering and Digital Manufacturing offerings are new at Cape Cod Community College. I felt that the MassBridge Project would allow me to refine our course syllabi and processes to best meet the U.S. advanced manufacturing workforce needs.

Additionally, we have state-of-the-art robotics and additive/3D manufacturing training facilities at Cape Cod Community College. I wanted to ensure that MassBridge supported the skills needed to leverage modern equipment and processes.

What is your contribution?

Elizabeth A. Moore: Our Roadmapping team (including Dr. Randy Kirchain and Dr. Frank Field) has developed five Workforce Roadmaps focused on skills needs for the advanced manufacturing technician and middle-skilled workforce over the next 3-5 years. Respondents were asked to characterize demand, hiring challenges, and training gaps for middle-skilled technical occupations specific to each industry. For additive/3D manufacturing, this included several engineering technician roles and an additive technician. The findings are based on interviews and surveys of operations managers from more than 150 advanced manufacturing firms across the United States.

Beth Unger: My primary contribution to the project was developing a straightforward process that mapped existing manufacturing curricula to emerging industry skills identified by Elizabeth’s Roadmapping team. The gaps from the analysis enable faculty members, like Rick from Cape Cod Community College, to systematically organize, plan, and prioritize where to insert or remove content to bridge the skills gap in advanced manufacturing.

Fredrick Bsharah: I am the faculty representative from Cape Cod Community College on the Curriculum Development Team. Working with the other community college faculty reps, we analyzed our curriculum against the skills needed for the advanced manufacturing technician and middle-skilled workforce, identified gaps in the course learning outcomes, and piloted revised courses. For example, Cape Cod offers an intro and an advanced solid modeling design course sequence.

The gaps related to process control, troubleshooting, and design for additive manufacturing (DfAM) were identified in assessing these courses. Working with our industry partners, two design projects were identified and defined so that these skills could be explicitly addressed in each course. These projects were integrated into the spring 2022-specific curriculum. In each course, the students created artifacts that showcased process control, troubleshooting, and DfAM. The industry partners critiqued the artifacts at each project’s mid-point and conclusion, and students were given constructive feedback.

We have also created tools, such as course learning outcome rubrics, for process validation of the skills. This verification and validation approach will be useful in maintaining the advanced manufacturing curriculum across the State.

How 3MF play a role in the project/curriculum?

Elizabeth A. Moore: 3MF helped play a critical role in introducing our team to additive and 3D manufacturing firms. Without their support, the interviews that underpin this study would not have been successful.

Fredrick Bsharah: From the MassBridge Curriculum Development perspective, I see two areas where the work of 3MF has direct overlap, manufacturing data exchange and manufacturing data retention. These concepts are embedded within our Information Management, Data Analysis and Synthesis, Interacting with Computers, and Process Control competencies. Being able to efficiently send and inter-operate with full-fidelity models with a mix of applications, platforms, services, and printers is a manufacturing technician skill that employers seek. Similarly, as additive manufacturing becomes more pervasive, regulations will dictate the need for new processes addressing long-term data retention and archiving of the additive manufacturing information. The 3MF format can play a strong role in meeting this need, and the MassBridge curriculum team is working to ensure the related skills are taught to students.

I would welcome any 3MF Consortium member to dive deeper into the work products we have created in MassBridge. Additionally, we at MassBridge are always looking to work with others to develop student projects and internships. Please reach out to me at fbsharah@capecod.edu.

For information about the MassBridge project and Roadmapping reports, please visit these links: