Meet 3MF Member, Materialise!

In this post we are highlighting 3MF Consortium member, Materialise, and their contributions to 3D Printing in the medical device space in particular.

Materialise incorporates 30 years of 3D printing experience into a range of software solutions and 3D printing services, which together form the backbone of the 3D printing industry. Their open and flexible solutions enable players in a wide variety of industries, including healthcare, automotive, aerospace, art and design, and consumer goods, to build innovative 3D printing applications that aim to make the world a better and healthier place. Headquartered in Belgium, with branches worldwide, Materialise combines the largest group of software developers in the industry with one of the largest and most complete 3D printing facilities in the world.

Q&A

What are the biggest challenges facing the 3D Printing/AM ecosystem?

From the medical applications standpoint, the biggest challenge facing hospital groups is insurance reimbursement for 3D printing workflows. We have discovered and are expanding medical 3D printing into multiple use-cases, with substantial benefits to patients, physicians, and institutions, but making medical devices inside a hospital or at a patient’s bedside is a novel approach. Healthcare has historically considered hospitals as providers, not manufacturers, but the advantages to point-of-care 3D printing continue to grow. Initiatives in the US are underway to build a path to reimbursement, which will provide the financial opportunity to continue this worthwhile practice.

What products and services do you provide in the 3D Printing/AM ecosystem?

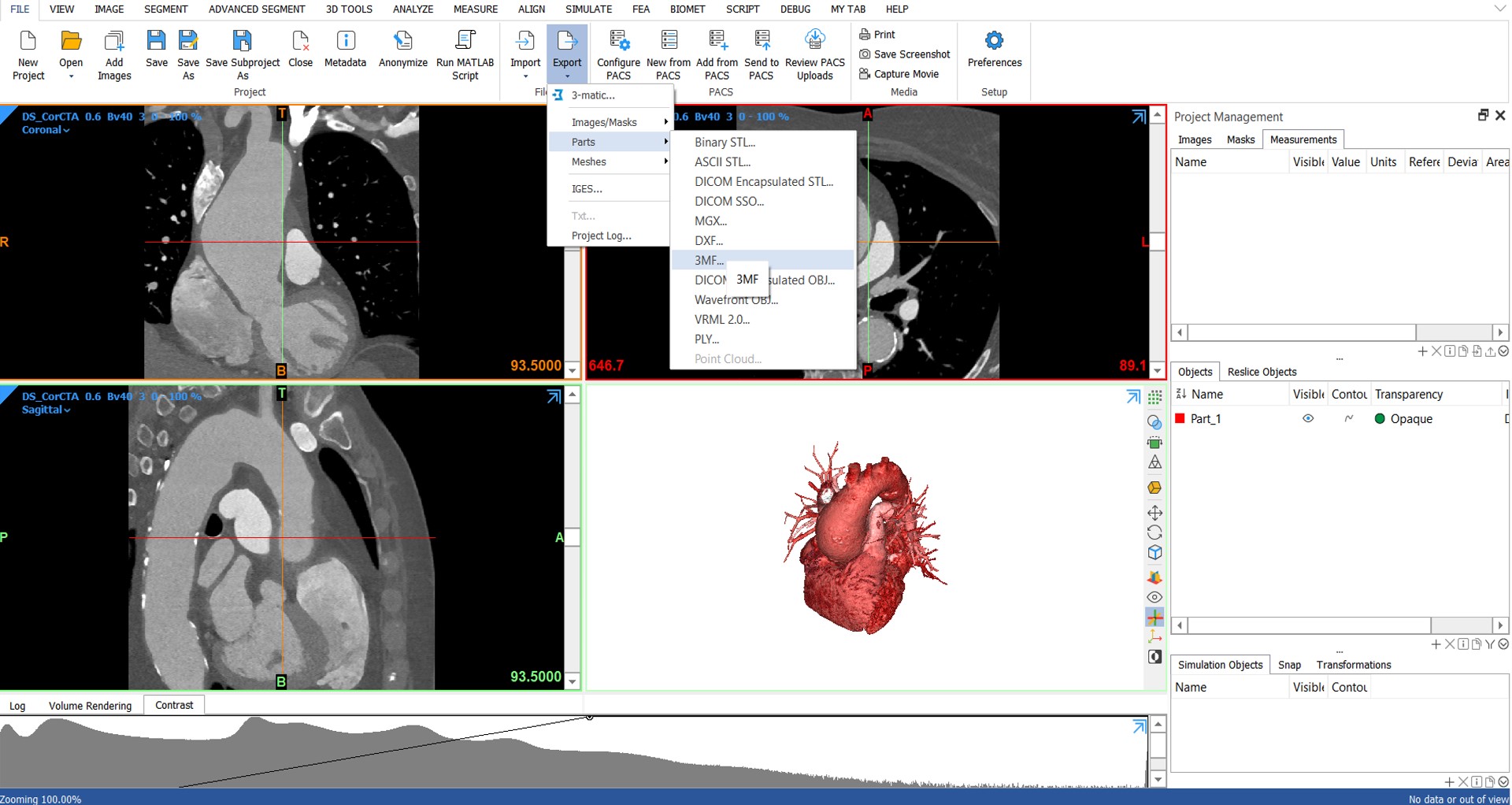

Materialise Medical is one branch of our 3D printing and additive manufacturing business that we’re particularly excited to share. In an effort to support our mission of creating a better and healthier world, researchers, engineers, and clinicians can use our tools to revolutionize personalized healthcare. We offer FDA cleared software tools for converting patient imaging data to CAD files, for enabling virtual surgical planning, and for engineering on anatomy and designing medical devices. For facilities set up to support point-of-care services, using our tools can help save time throughout the process and allows them to tailor their workflows to their specific needs. For those not yet prepared for in-house processing, our services allow them to outsource some of these same functions, including 3D printed anatomical models, virtual surgical planning, and personalized surgical guides and implants. For additional information, please visit medical.materialise.com.

Why did you decide to join 3MF?

3MF is becoming an increasingly popular 3D printing file format and has great momentum. Materialise wants to support our customers interested in expanding their operations to include the benefits of 3MF beyond the traditional stl and obj formats. Many 3D printing use-cases are emerging and growing, particularly in medical and clinical applications, and the evolving scope and adaptability of 3MF is attractive as user needs become more refined. Our goal is to make 3D printing as streamlined as printing 2-dimensionally on paper so users can devote more time to complex designs, and we believe supporting the 3MF consortium can help make this a reality.

Why do you feel 3MF is important to the 3D Printing/AM ecosystem?

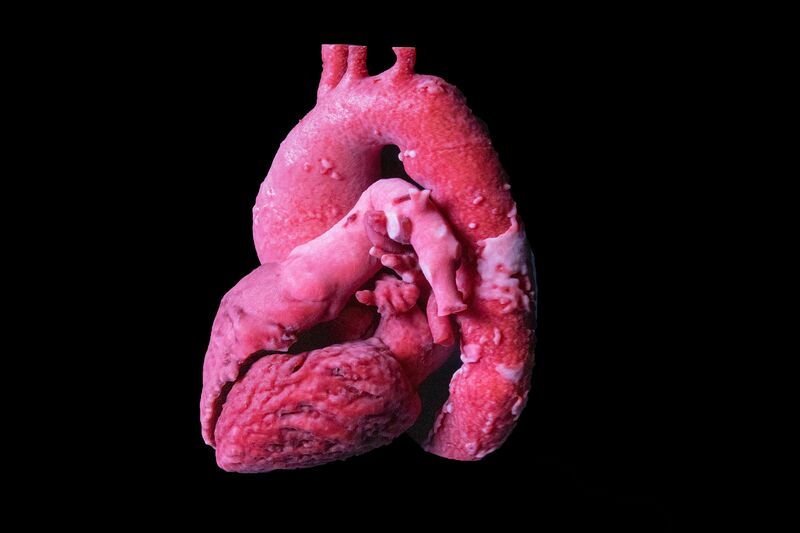

We have seen an ever-expanding ecosystem of 3D printing applications, from industry to hospitals. This expansion has been fueled by innovation and invention, and we have reached a point where traditional file formats are no longer able to translate every specification to manufacture these next-generation designs. 3MF solves this problem by including the necessary metadata, allowing users to make beautiful, highly functional parts. With the recent release of our segmentation software Mimics 24, we have added a feature for the realistic coloring of anatomical designs. 3D printed models using this feature have a striking resemblance to native tissue and make surgical simulation much more realistic.

What exciting developments do you expect to see in 3D Printing/AM over the coming months or years?

With an increased awareness of the value of having 3D printing capabilities in a hospital setting, particularly with some of the advantages in supply chain that were realized during the COVID-19 pandemic, we’re excited to see greater adoption of point-of-care 3D printing worldwide. There are both patient and institutional benefits to having these tools onsite, from better outcomes in medical procedures that are now tailored to the individual patient, to 3D printed nasal swabs rapidly and inexpensively built for COVID testing, to reduced inventory requirements for hospitals, and we believe expanded adoption will help further our mission for a better and healthier world.

We’re also enthusiastic about continued improvement in 3D printer technology. With manufacturers releasing faster, more affordable machines, high-quality medical-grade printers are becoming more accessible at every level of healthcare. This is coupled with new and innovative 3D printing materials, some of which more closely mimic actual human tissues or enable improved implant properties. New machines and materials further increase the value of hospital 3D printing, which in turn stimulates the development of novel, more effective and realistic healthcare applications.

With an increase in point-of-care 3D printing, we anticipate an evolution in use-cases. Today, anatomical models for specific patients are a common application for medical 3D printing. In the future, we’re eager to see the next generation of medical devices, including patient-specific instruments, implants, and prosthetics. The Materialise Mimics Innovation Suite enables the full workflow, from patient imaging to device design, and we’re excited to see how our customers apply these tools in new ways within their areas of expertise.