Additive Flow joins the 3MF Consortium as an Associate Member to help develop and communicate better communication of data for additive manufacturing.

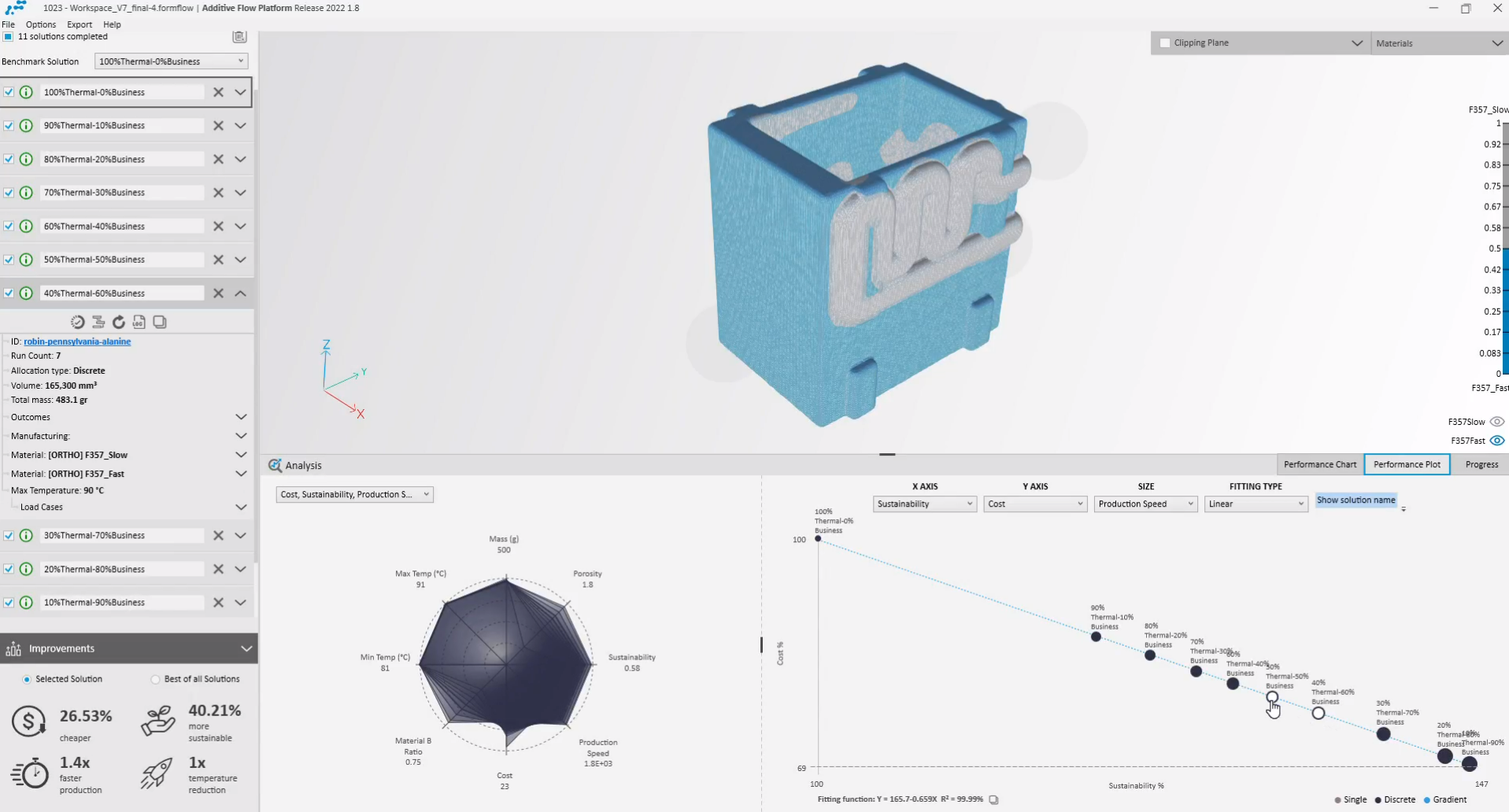

Additive Flow software helps improve part performance and print process, quality and speed leveraging companies existing data to develop AI derived smart parameters. Their approach is not a part design or optimization tool, but a process optimization tool that uses 3MF to communicate machine parameters to every voxel of a part or build.

In a recent example in collaboration with Zeiss, Autodesk and EOS, Additive Flow were able to use the 3MF Volumetric Extension to communicate optimized build parameters for a sensor housing unit, to reduce mass by 45%, increase production speed by 50% and thermal performance by 35% by modifying the build parameters within the volume of a single material part to produce variable material properties. To communicate this complexity without the 3MF Volumetric Extension would require multiple meshes exported and uploaded to build preparation software, to then assign different parameters to each shell which is prone to error, and potential for issues at the intersection between mesh boundaries.

With the 3MF Volumetric Extension, Additive Flow were able to export both the exterior mesh of the component for visualization (and addition of support structures if required) and each layer of the object as a bitmap stack with each pixel representing a voxel of material able to be assigned with information of requirements. This volumetric representation was then able to be read in to Autodesk Netfabb, where the various build parameters were defined, and then sent directly to manufacture with EOS laser Powder Bed Fusion system.

“Additive Flow’s smart parameter optimisation enables up to 200% faster print speeds and quality-assured successful production with metal additive manufacturing while leveraging the full capabilities of the 3MF file format, to ensure accuracy and no loss/errors in the transfer of data. Additive Flow views joining the 3MF consortium as the next logical step for maximising the Additive Flow approach.

Given the level of data created for optimisations, it is important that our own efficient workflows are matched by an equally as efficient workflow from 3MF.

Additive Flow’s one click export automates hours of manual work and reduces timescales to minutes. The resulting output provides a single file for Autodesk Netfabb to generate advanced toolpaths that are machine ready and ensure high quality, successful builds.“

Alexander Pluke, CEO, Additive Flow

“Additive Flow’s software is pushing the boundaries of what is possible in defining optimized designs by really thinking inside the box. Where other optimization tools are primarily concerned with the geometry of an object, Additive Flow optimizes what is happening inside the geometry, to deliver performance gains and manufacturing efficiencies not possible without addressing what is happening within the volume of the object.

The 3MF Consortium welcomes Additive Flow as a member to formalize a working relationship we have had for over two years, and we look forward to continuing to improve performance, production and efficiency in advanced manufacturing.“

Duann Scott, Executive Director, 3MF Consortium.

Trusted by industry leaders in AM build optimization for production and quality control such as Zeiss, Airbus and the National Physics Laboratory, Additive Flow know the importance of high resolution, accuracy and reliability of data transfer of not just geometry, but manufacturing parameters.