3MF in the Wild – Meet Oqton!

3MF in the Wild is a blog series where we will highlight innovative uses of the 3MF specification in the 3D Printing and Additive Manufacturing industries at large. For the first 3MF in the Wild post, we introduce Oqton!

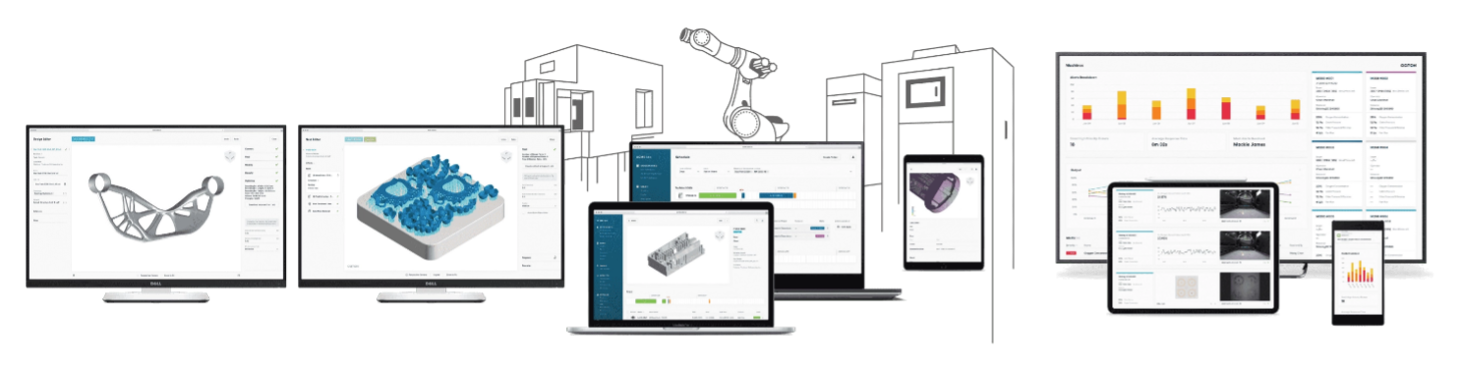

Oqton is a global SaaS company that believes that factories of the future will be powered by humans and machines working seamlessly together. The Oqton platform enables this and provides scalable, sustainable, and efficient manufacturing for any sized company. They have built a platform-agnostic, cloud-based manufacturing operating system that automates the end-to-end workflow across & beyond the production floor.

We recently had the opportunity to interview Oqton and dig into how the 3MF specification helps enable their product.

Q&A

What products or services does Oqton provide the additive manufacturing industry?

At Oqton, our agnostic manufacturing operating system automates the end-to-end workflow across and beyond the production floor. Oqton combines order tracking, latticing, build preparation, slicing, all relevant to Additive Manufacturing. For both AM and CAM processes, Oqton can facilitate order tracking, scheduling, traceability and data insights.

This is all done in one cloud-based platform that leverages Artificial Intelligence to automate every repetitive task and utilizes intelligent IoT capabilities to connect all of the equipment on the factory floor. This includes everything from plastic 3D printers, metal additive manufacturing machines, and even post-processing equipment.

When you ask where we position our software, we put it like this: Oqton empowers humans and machines to work seamlessly together. That, increasingly, is the key difference between manufacturing success and manufacturing failure.

What are the biggest challenges in the 3D Printing/AM industry?

Automation- there is still a lot of work such as healing of files, fixing errors that today have to be carried out manually, adding considerable time and costs to the process.

A good example of a specific use case is build preparation for laser powder bed fusion. There are many important factors like part orientation, support generation, and parameter assignment. A mistake can easily be made, and a failed print job can cost tens of thousands of dollars. Oqton provides our customers with the opportunity to create build preparation templates. We capture their knowledge and experience and couple it with our AI algorithms to automate the complete process. In this way, we speed up the process and lower costs while substantially decreasing human error and improve reproducibility. For our customers, this is invaluable.

When you reduce dependency on key operators, this also means that more people can program autonomously. You are no longer at the mercy of one key person’s holiday schedule or them falling sick. This also enables full end-to-end traceability, especially in regulated industries where full documentation is vital, such as medical and aerospace.

Ultimately, we see clients increase machine efficiency by faster programming and using advanced manufacturing equipment like welding robots and industrial 3D printers.

How does your product take advantage of 3MF?

Interoperability is key to the automated AM ecosystem. 3MF enables interoperability with products and services across the industry such that we are able to import geometries, lattices, and nests from other build preparation & design software and enhance interoperability with 3Dprinters. 3MF facilitates the import step where we take information from other SW into Oqton platform and the export step where we push info to the 3D printers. The 3MF format also makes it easier for end customers to use different brands of software and 3D printers, and combine CAM, MES, and IOT in one brand-agnostic platform.

Why do you feel 3MF is important to the 3D Printing/AM ecosystem?

A common file format helps software and hardware connect and speak the same language to each other.

At Oqton, we are using the 3MF format as a standard printers to help us “talk” to printers. We use it to exchange information with other software, as well. It is useful because it can handle 3Dgeometries, lattices, colors, and slices. This enables the end customer to move all types of information between different systems, software, and hardware.

The ultimate vision would be if everybody in the industry moves to a common standard. If everyone adopts one file format, it would make it easier for people, less work for developers, and end-users can use multiple brands without incurring interoperability challenges.

What exciting developments do you expect to see in 3D Printing/AM over the coming months or years?

The trends coming round the corner include, a big shift in focus from hardware to software, which includes the move to cloud-based platforms, and the use of AI to automate that process.

IoT connected machines produce lots of data, which in turn requires machine learning AI as the only way to process all that information. Operations will therefore rely more and more on automation to manage their workflows. How to up-skill their current workforce to take on new work responsibilities and work with automation is, therefore, both a coming trend and a challenge for the industry at large.

We also see a shift in manufacturing from using 3D printing just for prototyping towards its use within actual production. AM technologies will continue to scale towards production, but still be used ubiquitously for prototyping.

Finally, another trend we see is in areas of integration. Oqton has architected, developed, and built our end-to-end platform from scratch. In doing so, we have solved a lot of difficult problems and combined powerful data processing and management with a clean and intuitive interface. We feel that open-source industry standards such as 3MF, help enable this trend through interoperability.