At CDFAM Computational Design Symposium in NYC on October 2-3, 2024, Jan Orend who contributes to the development of the 3MF specification on behalf of EOS will be presenting the Volumetric Extension, that includes both implicit and voxel information to communicate not just geometry, but data within a given volume, in a highly efficient manner.

Can give us an overview of the 3MF Consortium and the role you play in its development?

The first time I encountered an L-PBF machine it felt like science fiction – just until I had to see the mesh based workflow and the tedious mesh repair process first hand.

Years later I found myself working in the software department at EOS, where I was again confronted with the limitations of the STL format.

Our customers were and still are challenging us with part designs with increasing complexity. I got the opportunity to represent EOS in the 3MF Consortium and I was immediately hooked.

The 3MF Consortium is the perfect place to address these challenges. Its members cover a broad range of the industry and work together in thriving collaboration to solve the interoperability challenges that are holding back the industry. I am glad to be part of this effort and to contribute to the development of the 3MF format, especially to drive the Implicit Extension.

Your presentation at CDFAM NYC introduces the new .3MF Volumetric and Implicit Extension. Could you explain what this extension entails and how it differs from existing capabilities of the 3MF format?

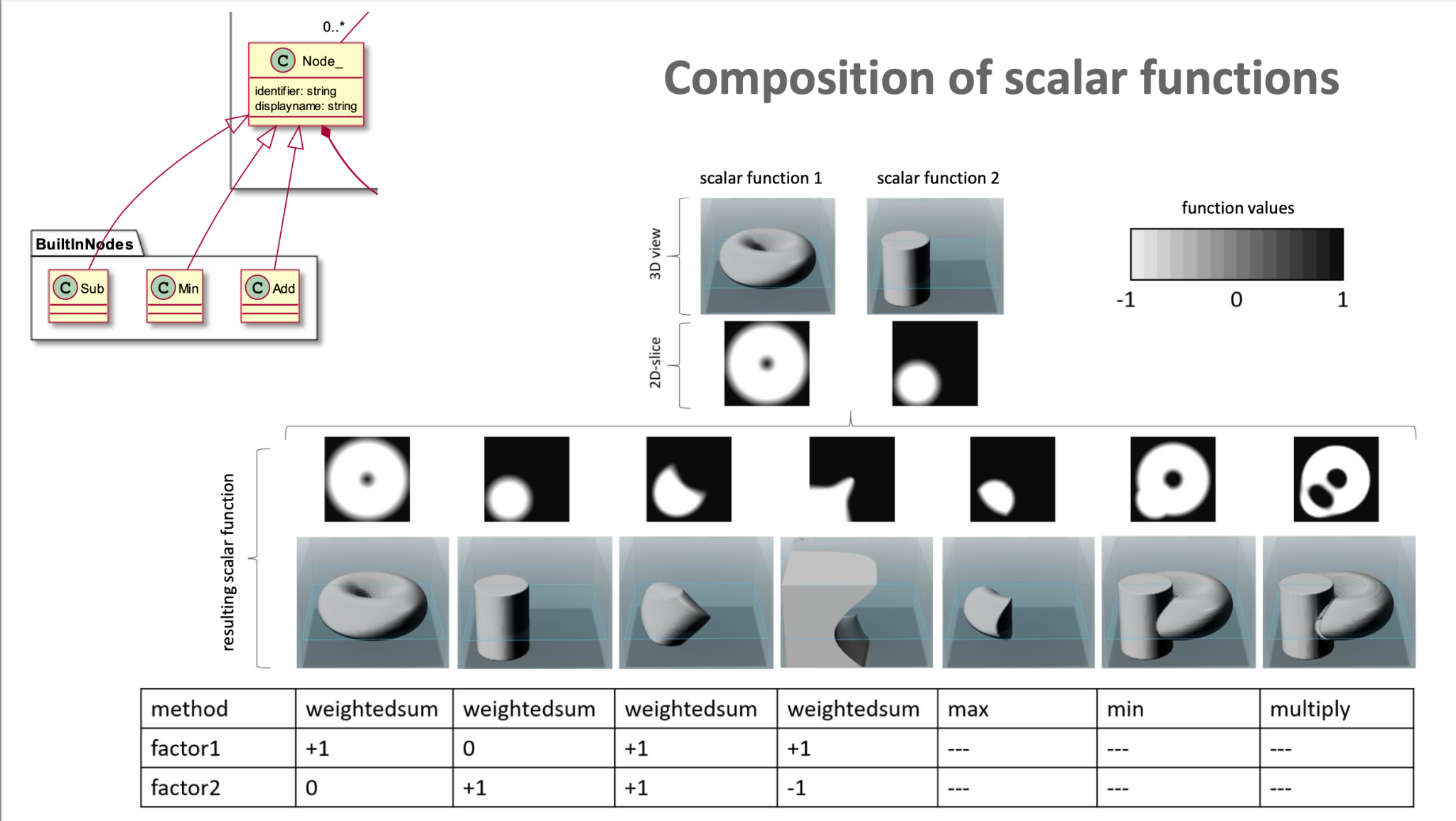

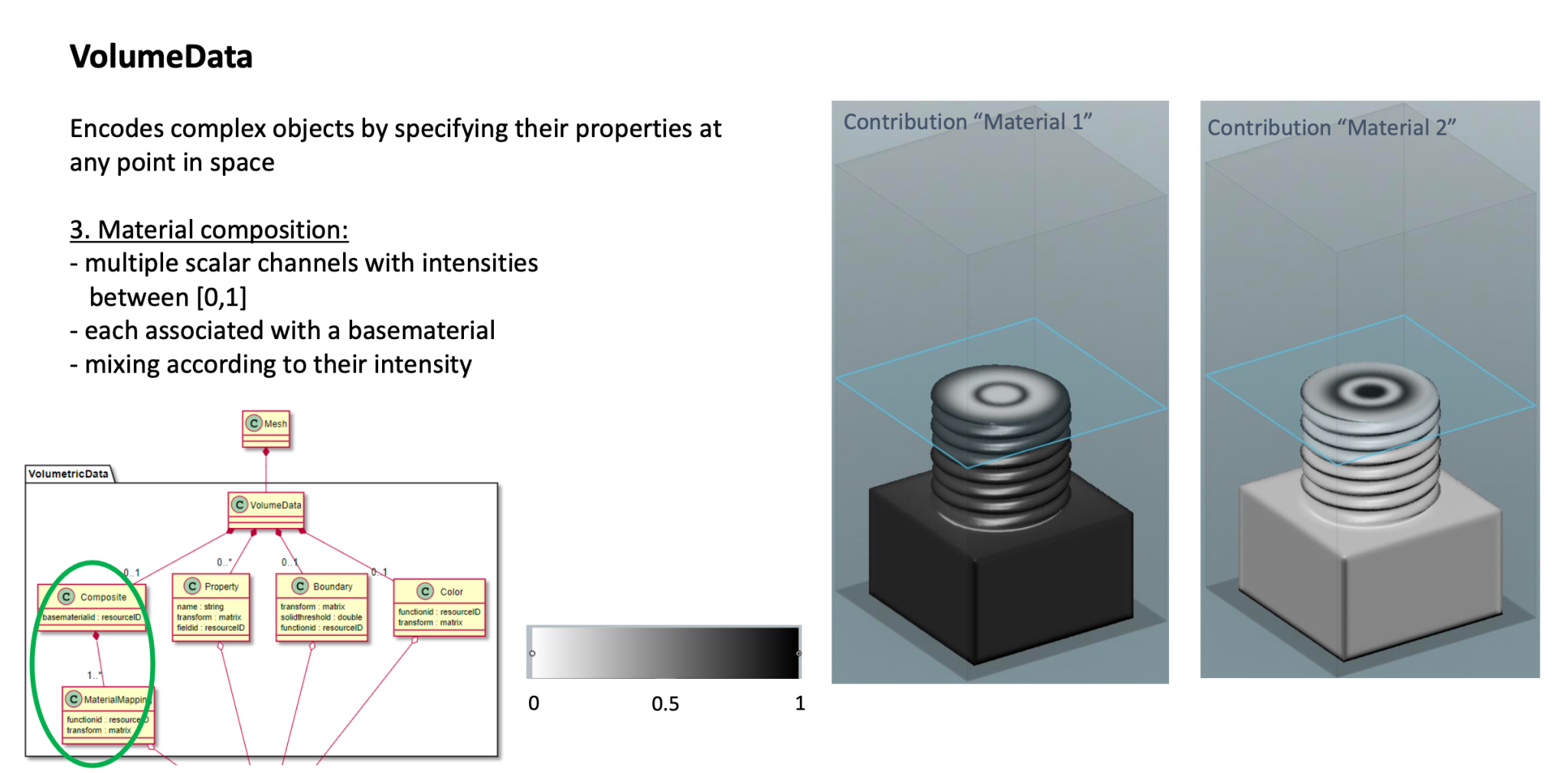

The Volumetric and Implicit Extension allow to define spatial functions, either by a stack of 2D images or by a mathematical function or a combination of both. These functions can be used to define the properties of a part, like material properties or color. But they can also be used to define the part geometry itself as a levelset.

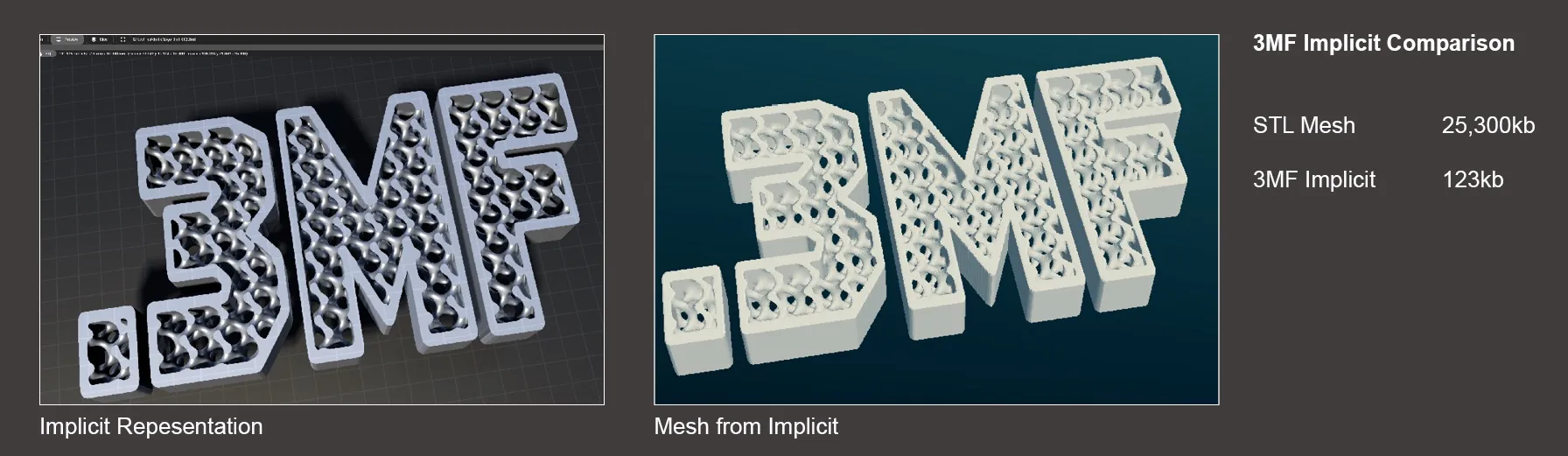

The implict extension allows us to define complex geometries without the need to tessellate them. This is a huge step forward for the industry, as it allows to communicate the data in a much more efficient way and to enable new applications that were not possible before.

How does the .3MF Volumetric Extension enable the communication of complex additive manufacturing data at the voxel and implicit levels? What are the benefits of this capability for designers and engineers?

For some geometries, like lattices or TPMS structures, the tessellation can be very inefficient and can lead to huge files, constraining the design freedom by the number triangles, while the underlying mathematical function is very simple.

Instead of moving GBs of data around, you can now communicate the same Design intent with a few KBs of data. The ability to represent spatial properties allows the design of parts with varying material properties, like controlling local density or stiffness or maybe even influencing the microstructure.

What key insights or lessons do you hope the audience will take away from your presentation at CDFAM in NYC?

I hope that the audience will understand the potential of the Volumetric and Implicit Extension and that they will be inspired to use it in their products.

I hope for a great adoption of the extension, and to see additive manufactured parts that leverage the potential of the utilization of spatial material properties and complex geometrical designs. And maybe after the presentation, some of the audience will be inspired to join the 3MF Consortium and to contribute to the development of the 3MF format.